英國(guó)帕金斯2506電噴柴油發(fā)動(dòng)機(jī)維修保養(yǎng)故障代碼排除查詢

英國(guó)帕金斯2506電噴柴油發(fā)動(dòng)機(jī)維修保養(yǎng)故障排除

2506- 15

Industrial

Engine

![]()

![]() Important Safety

Important Safety

Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others. You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When

replacement

parts

are

required

for

this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

![]() KENR6224

KENR6224

3

Table of Contents

Table

of

Contents

CID 0003 FMI 11 ................................................... 55

CID 0004 FMI 11 ................................................... 55

CID 0005 FMI 11 ................................................... 56

CID 0006 FMI 11 ................................................... 56

Troubleshoot ing Section

Electronic Troubleshooting

System Overview .................................................... 5

Glossary .................................................................. 7

Electronic Service Tools ........................................ 10

Replacing the ECM ............................................... 12

Self-Diagnostics .................................................... 13

Sensors and Electrical Connectors ....................... 14

Engine Wiring Information .................................... 18

Programming Parameters

Programming Parameters ..................................... 21

Factory Passwords ............................................... 21

Factory Passwords Worksheet ............................. 21

Flash Programming .............................................. 22

Injector Trim File ................................................... 23

System Configuration Parameters

System Configuration Parameters ........................ 24

Troubleshooting without a Diagnostic Code

Alternator Noise .................................................... 31

Alternator Will Not Charge .................................... 31

Battery .................................................................. 31

Can Not Reach Top Engine RPM ......................... 32

Coolant in Engine Oil ............................................ 33

Coolant Temperature Is Too High ......................... 34

ECM Will Not Accept Factory Passwords ............. 34

ECM Will Not Communicate with Other Systems or

Display Modules .................................................. 34

Electronic Service Tool Will Not Communicate with

ECM .................................................................... 35

Engine Cranks but Will Not Start .......................... 36

Engine Has Early Wear ........................................ 37

Engine Misfires, Runs Rough or Is Unstable ........ 38

Engine Oil in Cooling System ............................... 39

Engine Vibration ................................................... 39

Engine Will Not Crank ........................................... 40

Excessive Black Smoke ........................................ 40

Excessive Engine Oil Consumption ...................... 41

Excessive Fuel Consumption ............................... 42

Excessive Valve Lash ........................................... 43

Excessive White Smoke ....................................... 43

Fuel Dilution of Engine Oil .................................... 44

Intermittent Engine Shutdown ............................... 45

Low Engine Oil Pressure ...................................... 46

Low Power ............................................................ 46

Mechanical Noise (Knock) in Engine .................... 47

Noise Coming from Cylinder ................................. 48

Poor Acceleration or Response ............................ 49

Valve Rotator or Spring Lock Is Free .................... 50

Troubleshooting with a Diagnostic Code

Flash Codes .......................................................... 51

Diagnostic Codes .................................................. 51

Diagnostic Code Cross Reference ....................... 52

CID 0001 FMI 11 ................................................... 54

CID 0002 FMI 11 ................................................... 55

CID 0041 FMI 03 .................................................. 56

CID 0041 FMI 04 .................................................. 57

CID 0091 FMI 08 .................................................. 57

CID 0100 FMI 03 .................................................. 57

CID 0100 FMI 04 .................................................. 57

CID 0110 FMI 03 ................................................... 58

CID 0110 FMI 04 ................................................... 58

CID 0168 FMI 02 .................................................. 58

CID 0172 FMI 03 .................................................. 59

CID 0172 FMI 04 .................................................. 59

CID 0174 FMI 03 .................................................. 59

CID 0174 FMI 04 .................................................. 59

CID 0190 FMI 02 .................................................. 60

CID 0190 FMI 09 .................................................. 60

CID 0190 FMI 11 ................................................... 60

CID 0190 FMI 12 .................................................. 61

CID 0247 FMI 09 .................................................. 61

CID 0248 FMI 09 .................................................. 61

CID 0253 FMI 02 .................................................. 61

CID 0254 FMI 12 .................................................. 62

CID 0261 FMI 13 .................................................. 62

CID 0262 FMI 03 .................................................. 62

CID 0262 FMI 04 .................................................. 63

CID 0268 FMI 02 .................................................. 63

CID 0273 FMI 03 .................................................. 63

CID 0273 FMI 04 .................................................. 63

CID 0274 FMI 03 .................................................. 64

CID 0274 FMI 04 .................................................. 64

CID 0342 FMI 02 .................................................. 64

CID 0342 FMI 11 ................................................... 65

CID 0342 FMI 12 .................................................. 65

CID 0799 FMI 12 .................................................. 65

CID 1690 FMI 08 .................................................. 66

Troubleshooting with an Event Code

Event Codes ........................................................ 67

E162 High Boost Pressure ................................... 69

E360 Low Engine Oil Pressure ............................. 70

E361 High Engine Coolant Temperature .............. 71

E362 Engine Overspeed ....................................... 72

E363 High Fuel Supply Temperature .................... 72

E368 High Intake Manifold Air Temperature ......... 73

Diagnostic Functional Tests

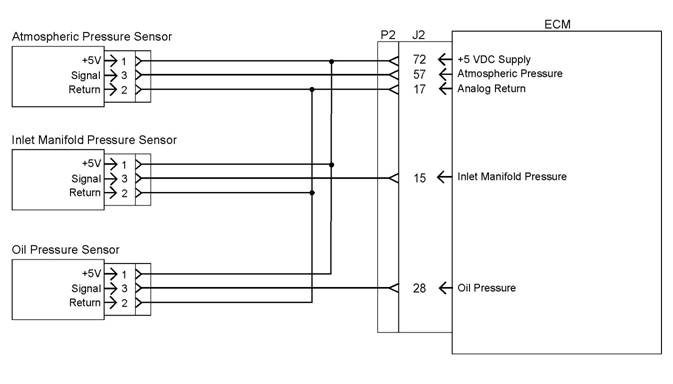

5 Volt Engine Pressure Sensor Supply Circuit -

Test ..................................................................... 75

CAN Data Link Circuit - Test ................................. 81

Data Link Circuit - Test .......................................... 85

ECM Memory - Test .............................................. 88

Electrical Connectors - Inspect ............................. 90

Electrical Power Supply Circuit - Test ................... 94

Engine Pressure Sensor Open or Short Circuit -

Test ..................................................................... 97

Engine Speed/Timing Sensor Circuit - Test ........ 103

Engine Temperature Sensor Open or Short Circuit -

Test .................................................................... 110

Indicator Lamp Circuit - Test ................................ 115

Injector Solenoid Circuit - Test ............................. 119

Speed Control (Analog) - Test ............................ 126

![]() 4

4

Table of Contents

KENR6224

Speed Control (PWM) - Test ............................... 129

Switch Circuits - Test .......................................... 134

Calibration Procedures

Engine Speed/Timing Sensor - Calibrate ............ 138

Index Section

Index ................................................................... 140

![]()

![]() KENR6224

KENR6224

5

Troubleshooting Section

Troubleshoot ing

Section

Ele ct ron ic

Trou bl es hoot ing

System Overview

i02547521

System Operation

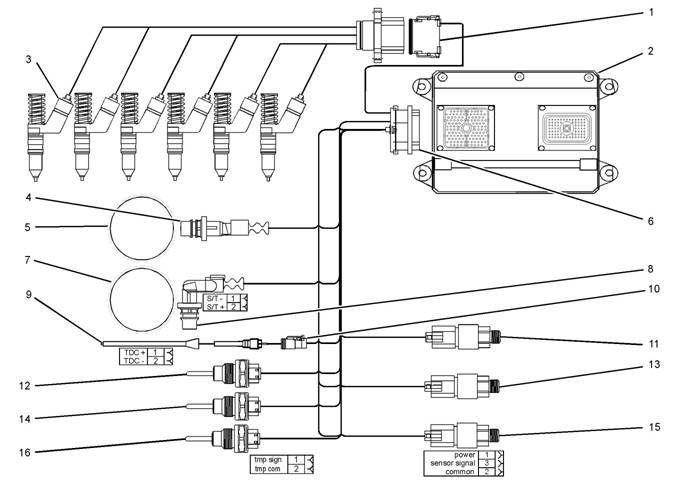

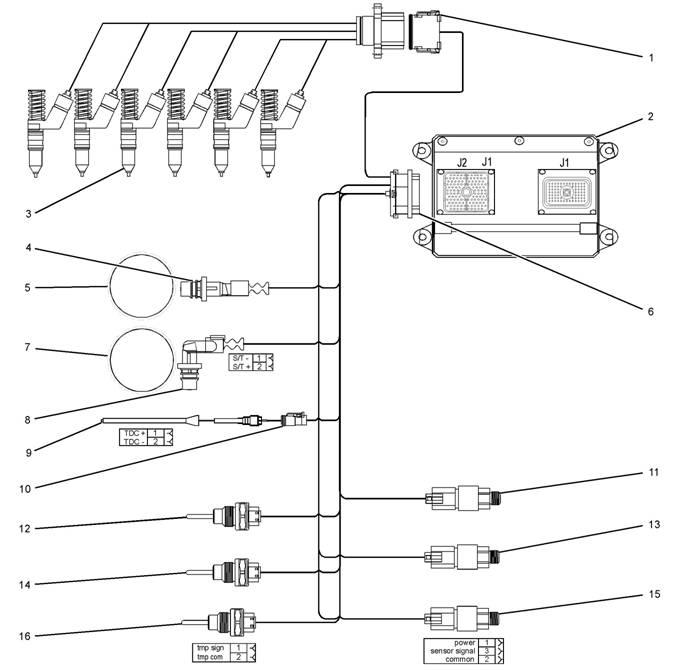

Illustration 1

Block diagram for the 2506-15 engine

(1) 12 Pin Connector

(2) Electronic Control Module (ECM)

(3) Electronic Unit Injectors

(4) Crankshaft Position Sensor

(5) 36 - 1 Tooth Gear

(6) 120 Pin Connector

(7) 36 + 1 Tooth Gear

(8) Camshaft Position Sensor

(9) Timing Calibration Probe

(10) Timing Calibration Probe Connector

(11) Atmospheric Pressure Sensor

(12) Inlet Manifold Temperature Sensor

g01277565

(13) Inlet Manifold Pressure Sensor

(14) Coolant Temperature Sensor

(15) Engine Oil Pressure Sensor

(16) Fuel Temperature Sensor

This engine is electronically controlled. Each cylinder

has an electronic unit injector. The Electronic Control

Module (ECM) sends a signal to each injector

solenoid in order to control the operation of the fuel

injection system.

![]() 6

6

Troubleshooting Section

KENR6224

Electronic Cont rols

The electronic system consists of the following

components: the ECM, the Mechanically Actuated

Electronically Controlled Unit Injectors (MEUI), the

wiring harness, the switches, and the sensors. The

ECM is the computer. The flash file is the software

for the computer. The flash file contains the operating

maps. The operating maps define the following

characteristics of the engine:

• Horsepower

• Torque curves

The ECM determines the timing and the amount of

fuel that is delivered to the cy linders. These decisions

are based on the ac tual conditions and/or on the

desired conditions at any given time.

The ECM compares the desired engine speed to

the actual engine speed. The actual engine speed is

determined through the engine speed/timing sensor.

The desired engine speed is determined with the

following factors:

• Throttle signal

• Other input signals from sensors

• Certain diagnostic codes

If the desired engine speed is greater than the actual

engine speed, the ECM injects more fuel in order to

increase the actual engine speed.

Fuel Injection

The ECM controls the amount of fuel that is injected

by varying the signals to the injectors. The injector will

pump fuel only if the injector solenoid is energized.

The ECM sends a high voltage signal to the solenoid.

This high voltage signal energizes the solenoid. By

controlling the timing and the duration of the high

voltage signal, the ECM can c ontrol injection timing

and the ECM can control the amount of fuel that is

injected.

The ECM limits engine power during cold mode

operation and the ECM modifies injection timing

during cold mode operation. Cold mode operation

provides the following benefits:

• Increased cold weather starting capability

• Reduced warm-up time

• Reduced white smoke

Cold mode is activated whenever the engine

temperature falls below a predetermined value. Cold

mode remains active until the engine temperature

rises above a predetermined value or until a time

limit is exceeded.

The flash file inside the ECM sets certain limits on

the amount of fuel that can be injected. The “FRC

Fuel Limit” is used to control the air/fuel ratio for

control of emissions. The “FRC Fuel Limit” is a limit

that is based on the turbocharger outlet pressure.

A higher turbocharger outlet pressure indicates that

there is more air in the cylinder. When the ECM

senses a higher turbocharger outlet pressure, the

ECM increases the “FRC Fuel Limit”. When the ECM

increases the “FRC Fuel Limit”, the ECM allows

more fuel into the cylinder. The “FRC Fuel Limit” is

programmed into the ECM at the factory. The “FRC

Fuel Limit” cannot be changed.

The “Rated Fuel Limit” is a limit that is based on the

power rating of the engine and on engine rpm. The

“Rated Fuel Limit” is similar to the rack stops and to

the torque spring on a mechanically governed engine.

The “Rated Fuel Limit” provides the power curves

and the torque curves for a specific engine family and

for a spec ific engine rating. The “Rated Fuel Limit” is

programmed into the ECM at the factory. The “Rated

Fuel Limit” cannot be changed.

Once the ECM determines the amount of fuel that

is required, the ECM must determine the timing of

the fuel injection. The ECM uses the signal from the

camshaft position sensor to c alculate the top center

pos ition of eac h cylinder . The ECM decides when

fuel injection should occur relative to the top center

pos ition and the ECM provides the signal to the

injector at the desired time. The ECM adjusts timing

for optimum engine performance, for optimum fuel

economy, and for optimum control of white smoke.

Programmable Parameters

Certain parameters that affect the engine operation

may be changed with the Perkins Electronic

Service Tool (EST). The parameters are stored

in the ECM, and some parameters are protected

from unauthorized changes by passwords. These

pas swords are c alled factory passwords.

Passwords

Several system configuration parameters and most

logged events are protected by factory passwords .

Factory passwords are available only to Perkins

dealers and distributors. Refer to Troubleshooting,

“Factory Passwords” for additional information.

![]() KENR6224

KENR6224

7

Troubleshooting Section

i02554801

Crankshaft Position Sensor

– This sensor

Glossary

Active Diagnostic Code

– An active diagnostic

determines the position of the crankshaft during

engine operation. If the crankshaft position sensor

fails during engine operation, the camshaft position

sensor is used to provide the signal.

Data Link – The Data Link is a serial communication

code alerts the operator or the service technician that

an electronic system malfunction is currently present.

Refer to the term “Diagnostic Code” in this glossary.

Adaptive Trim – This is a software process that is

performed in the Electronic Control Module (ECM)

that optimizes engine performance.

Alternating Current (AC) – Alternating current is an

electric current that reverses direction at a regular

interval that is reoccurring.

Before Top Center (BTC) – BTC is the 180 degrees

of crankshaft rotation before the piston reaches the

top dead center position in the normal direction of

rotation.

Breakout Harness – A breakout harness is a

test harness that is designed to connect into the

engine harness. This connection allows a normal

circuit operation and the connection simultaneously

provides a Breakout T in order to measure the

signals.

Bypass Circuit – A bypass circuit is a circuit that is

used as a substitute circuit for an existing circuit. A

bypass circ uit is typically used as a test circuit.

Camshaft Position Sensor – This sensor

determines the position of the camshaft during

engine operation. If the crankshaft position sensor

fails during engine operation, the camshaft position

sensor is used to provide the signal.

CAN Data Link (see also J1939 CAN Data Link) –

The CAN Data Link is a serial communications

port that is used for communication with other

microprocessor based devices.

Code – Refer to “Diagnostic Code” or “Event Code”.

Communication Adapter Tool – The

communication adapter provides a communication

link between the ECM and the electronic service tool.

Component Identifier (CID) – The CID is a number

that identifies the specific component of the electronic

control system that has experienced a diagnostic

code.

Coolant Temperature Sensor – The coolant

temperature sensor detects the engine coolant

temperature for all normal operating conditions and

for engine monitoring.

port that is used for communication with other devices

such as the electronic service tool.

Derate – Certain engine conditions will generate

event codes. Also, engine derates may be applied.

The map for the engine derate is programmed into

the ECM software. The derate can be one or more of

3 types: reduction of rated power, reduction of rated

engine speed, and reduction of rated machine speed

for OEM products.

Desired Engine Speed – The desired engine speed

is input to the electronic governor within the ECM.

The electronic governor uses the signal from the

throttle position sensor, the engine speed/timing

sensor, and other sensors in order to determine the

desired engine speed.

Diagnostic Code – A diagnostic code is sometimes

referred to as a fault code. These codes indicate an

electronic system malfunction.

Diagnostic Lamp – A diagnostic lamp is sometimes

called the check engine light. The diagnostic lamp

is used to warn the operator of the presence of

an active diagnostic code. The lamp may not be

included in all applications.

Digital Sensor Return – The common line (ground)

from the ECM is used as ground for the digital

sensors.

Digital Sensors – Digital sensors produce a pulse

width modulated signal. Digital sensors are supplied

with power from the ECM.

Digital Sensor Supply – The power supply for the

digital s ensors is provided by the ECM.

Direct Current (DC) – Direct current is the type of

current that flows consistently in only one direction.

DT, DT Connector, or Deutsch DT – This is a type

of connector that is used on Perkins engines. The

connectors are manufactured by Deutsch.

Duty Cycle – Refer to “Pulse Width Modulation”.

Electronic Engine Control – The electronic

engine control is a complete electronic system.

The electronic engine control monitors the engine

operation under all conditions. The electronic engine

control also controls the engine operation under all

conditions.

![]() 8

8

Troubleshooting Section

KENR6224

Electronic Control Module (ECM) – The ECM

7

– The mechanic al system is not responding

is the control computer of the engine. The ECM

provides power to the electronics. The ECM monitors

data that is input from the sensors of the engine. The

ECM acts as a governor in order to control the speed

and the power of the engine.

Electronic Service Tool – The electronic service

tool allows a computer (PC) to communicate with the

ECM.

Engine Monitoring – Engine Monitoring is the part

of the electronic engine control that monitors the

sensors. This also warns the operator of detected

faults.

Engine Oil Pressure Sensor – The engine oil

pressure sensor measures engine oil pressure. The

sensor sends a signal to the ECM that is dependent

on the engine oil pressure.

Engine Position Sensor – An engine position

sensor is a hall effect switc h that provides a digital

signal to the ECM. The ECM interprets this signal as

the crankshaft position and the engine speed. Two

sensors are used to provide the speed and timing

signals to the ECM. The crankshaft position sensor

is associated with the crankshaft and the camshaft

position sensor is associated with the camshaft.

Event Code – An event code may be activated

in order to indicate an abnormal engine operating

condition. These codes usually indicate a mechanical

fault instead of an electrical system fault.

Failure Mode Identifier (FMI) – This identifier

indicates the type of failure that is associated with

the component. The FMI has been adopted from the

SAE practice of J1587 diagnostics. The FMI follows

the parameter identifier (PID) in the descriptions of

the fault code. The descriptions of the FMIs are in

the following list.

0 – The data is valid but the data is above the normal

operational range.

1 – The data is valid but the data is below the normal

operational range.

2 – The data is erratic, intermittent, or incorrect.

3 – The voltage is above normal or the voltage is

shorted high.

4 – The voltage is below normal or the voltage is

shorted low.

5 – The current is below normal or the circuit is open.

6 – The current is above normal or the circuit is

grounded.

properly.

8 – There is an abnormal frequency, an abnormal

pulse width, or an abnormal time period.

9 – There has been an abnormal update.

10 – There is an abnormal rate of change.

11 – The failure mode is not identifiable.

12 – The device or the component is damaged.

Flash File – This file is software that is inside

the ECM. The file contains all the instructions

(software) for the ECM and the file contains the

performance maps for a specific engine. The file may

be reprogrammed through flash programming.

Flash Programming – Flash programming is the

method of programming or updating an ECM with

an electronic servic e tool over the data link instead

of replacing components.

Fuel Injector E-Trim – Fuel injector E-trim is a

software process that allows precise control of fuel

injectors by parameters that are programmed into

the ECM for eac h fuel injector. With the use of the

electronic service tool, the service technician can

read status information for the E-Trim. Data for

E-Trim can also be programmed.

FRC – See “Fuel Ratio Control”.

Fuel Ratio Control (FRC) – The FRC is a limit that

is based on the control of the ratio of the fuel to air.

The FRC is used for purposes of emission control.

When the ECM senses a higher intake manifold

air pressure (more air into the cylinder), the FRC

increases the FRC Limit (more fuel into the cylinder).

Full Load Setting (FLS) – The FLS is the parameter

that represents the fuel system adjustment. This

adjustment is made at the factory in order to fine tune

the fuel system. The correct value for this parameter

is stamped on the engine information ratings plate.

This parameter must be programmed.

Full Torque Setting (FTS) – The FTS is the

parameter that represents the adjustment for the

engine torque. This adjustment is made at the factory

in order to fine tune the fuel system. This adjustment

is made in conjunction with the FLS. This parameter

must be programmed.

Harness – The harness is the bundle of wiring

(loom) that connects all components of the electronic

system.

![]()

![]() KENR6224

KENR6224

9

Troubleshooting Section

Hertz (Hz)

– Hertz is the measure of electrical

Password – A password is a group of numeric

frequency in cycles per second.

Injector Codes – The injector codes or injector trim

codes are numeric codes or alphanumeric codes

that are etched or stamped on individual electronic

unit injectors. These codes are used to fine tune the

fuel delivery.

Injector Trim Files – Injector trim files are

downloaded from a disk to the ECM. The injector

trim files compensate for variances in manufacturing

of the electronic unit injector and for the life of the

electronic unit injector. The serial number for the

electronic unit injector must be obtained in order to

retrieve the correct injector trim file.

Intake Manifold Air Temperature Sensor – The

intake manifold air temperature sensor detec ts the

air temperature in the intake manifold. The ECM

monitors the air temperature and other data in the

intake manifold in order to adjust injection timing and

other performance functions .

Intake Manifold Pressure Sensor – The Intak e

Manifold Pressure Sensor measures the pressure

in the intake manifold. The pressure in the intake

manifold may be different to the pressure outside

the engine (atmospheric pressure). The difference

in pressure may be caused by an increase in air

pressure by a turbocharger (if equipped).

Integrated Electronic Controls – The engine is

designed with the electronic controls as a necessary

part of the system. The engine will not operate

without the electronic controls.

J1939 CAN Data Link – This data link is a SAE

standard diagnostic c ommunications data link that

is used to communicate between the ECM and the

electronic dev ices.

Logged Diagnostic Codes – Logged diagnostic

codes are codes which are stored in the memory.

These codes are meant to be an indicator of

possible causes for intermittent faults. Refer to the

term “Diagnostic Code” in this glossary for more

information.

OEM – OEM is an abbreviation for the Original

Equipment Manufacturer. This is the manufacturer of

the machine or the vehicle that uses the engine.

Open Circuit – An open circuit is a condition that is

caused by an open switch, or by an elec trical wire

or a connection that is broken. When this condition

exists, the signal or the supply voltage can no longer

reach the intended destination.

Parameter – A parameter is a value or a limit that

is programmable. This helps determine specific

characteristics or behaviors of the engine.

|

that is designed to restrict acc ess to parameters. The

electronic system requires correct passwords in order

to change some parameters (Factory Passwords).

Refer to Troubleshooting, “Factory Passwords” for

more information.

Personality Module – See “Flash File”.

Power Cycled – Power cycled happens when power

to the ECM is cycled: ON, OFF, and ON. Power

cycled refers to the action of cycling the k eyswitch

from any position to the OFF position, and to the

START/RUN position.

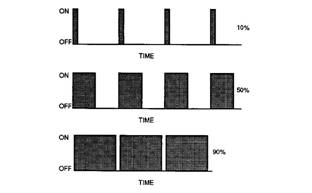

Pulse Width Modulation (PWM) – The PWM is a

signal that consists of pulses that are of variable

width. These pulses occur at fixed intervals. The ratio

of “TIME ON” versus total “TIME OFF” c an be varied.

This ratio is also referred to as a duty cycle.

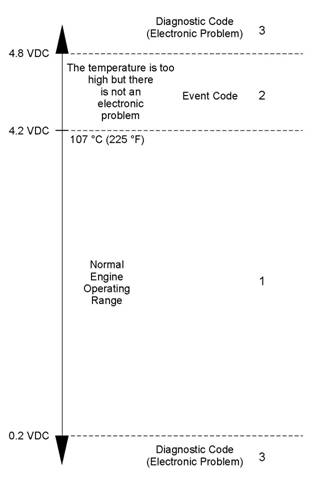

Illustration 2

Rated Fuel Limit – This is a limit that is based on

the power rating of the engine and on the engine rpm.

The Rated Fuel Limit enables the engine power and

torque outputs to conform to the power and torque

curves of a specific engine model. These limits are in

the flash file and these limits cannot be changed.

Reference Voltage – Reference voltage is a

regulated voltage and a steady voltage that is

supplied by the ECM to a sensor. The reference

voltage is used by the sensor to generate a signal

voltage.

Relay – A relay is an electromec hanical switc h. A

flow of electricity in one circuit is used to control the

flow of electricity in another circuit. A small current or

voltage is applied to a relay in order to switch a much

larger current or voltage.

Sensor – A sens or is a device that is used to

detect the current value of pressure or temperature,

or mechanical movement. The information that is

detected is converted into an electrical signal.

| |||||||||||||||||||||||||||

Troubleshooting Section

KENR6224

Short Circuit – A short circuit is a condition that has

an electrical circuit that is inadvertently connected to

an undesirable point. An example of a short circuit

is a wire which rubs against a vehicle frame and

this rubbing eventually wears off the wire insulation.

Electrical contact with the frame is made and a s hort

circuit results.

Signal – The signal is a voltage or a waveform that

is used in order to transmit information ty pically from

a sensor to the ECM.

•

•

•

•

•

Obtain data.

Diagnose faults.

Read parameters.

Program parameters.

Calibrate sensors.

Supply Voltage – The supply voltage is a continuous

voltage that is supplied to a component in order to

provide the elec trical power that is required for the

component to operate. The power may be generated

by the ECM or the power may be battery voltage that

is supplied by the engine wiring.

System Configuration Parameters – System

configuration parameters are parameters that affect

emiss ions and/or operating charac teristics of the

engine.

Tattletale – Certain parameters that affect the

operation of the engine are stored in the ECM.

These parameters can be changed by use of the

electronic service tool. The tattletale logs the number

of changes that have been made to the parameter.

The tattletale is stored in the ECM.

Throttle Position – The throttle position is the

interpretation by the ECM of the signal from the

throttle position sensor or the throttle switch.

Timing Calibration – The timing calibration is the

adjustment of an electrical signal. This adjustment is

made in order to correct the timing error between the

camshaft and the engine speed/timing sensors or

between the crankshaft and the engine speed/timing

sensors.

Top Center Position – The top center position refers

to the crankshaft position when the engine piston

position is at the highest point of travel. The engine

must be turned in the normal direction of rotation in

order to reach this point.

Total Tattletale – The total tattletale is the total

number of changes to all the parameters that are

stored in the ECM.

i02547729

Electronic Service Tools

Perkins Electronic Service Tools are designed to help

the service technician:

Required Service Tools

The tools that are listed in Table 1 are required in

order to enable a service technician to perform the

procedures.

Table 1

Two short jumper wires are needed to check the

continuity of some wiring harness circuits by shorting

two adjacent terminals together in a connector. A

long extension wire may also be needed to check the

continuity of some wiring harness circuits.

Perkins Electronic Service Tool

(EST)

The Perkins EST can display the following

information:

• Parameters

• Event codes

• Diagnostic codes

• Engine configuration

![]()

![]()

![]() KENR6224

KENR6224

11

Troubleshooting Section

The Perkins EST can be used by the technician to

perform the following functions:

• Diagnostic tests

• Sensor calibration

• Flash programming

• Set parameters

Table 2 lists the service tools that are required in

order to use Perkins EST.

Table 2

Connecting Perkins EST and the

Communication Adapter II

|

Service Tools for the Use of Perkins EST | |

|

Part Number |

Description |

|

-(1) |

Personal Computer (PC) |

|

-(1) |

Single user license for Perkins EST |

|

-(1) |

Data Subscription for All Engines |

|

27610251 |

Communi cation Adapter Gp |

|

27610164(2) |

Adapter Cable As |

(1)

(2)

Refer to the Perkins Engine Company Limited.

The 27610164 Adapter Cable As is required to connect to the

USB port on computers that are not equipped with a RS232

serial port.

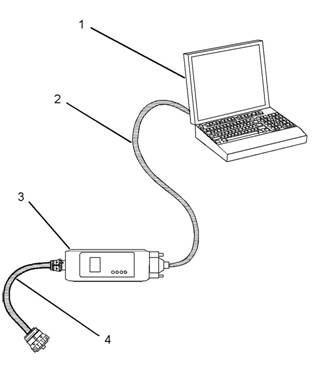

Illustration 3

(1) Personal computer (PC)

g01115382

Note: For more information regarding the use of

Perkins EST and the PC requirements for Perkins

EST, refer to the documentation that accompanies

your Perkins EST software.

(2) Adapter Cable (RS232 Port)

(3) Communication Adapter As

(4) Adapter Cable As

Note: Items (2), (3), and (4) are part of the 27610251

Communication Adapter Gp.

Use the following procedure in order to c onnect

Perkins EST and the Communication Adapter II.

1. Turn the keyswitch to the OFF position. If the

keyswitch is not in the OFF position, the engine

may start.

2. Connect cable (2) between the “COMPUTER”

end of communication adapter (3) and the RS232

serial port of PC (1).

Note: An adapter cable assembly is required to

connect to the USB port on computers that are not

equipped with a RS232 serial port.

3. Connect cable (4) between the “DATA LINK” end

of communication adapter (3) and the diagnostic

connector.

![]()

![]()

![]() 12

12

Troubleshooting Section

KENR6224

4.

Place the keyswitch in the ON position. If the

Perkins EST and the communication adapter

do not communicate with the Elec tronic Control

Module (ECM), refer to the diagnostic procedure

Troubleshooting, “Electronic Service Tool Will Not

Communicate With ECM”.

i02548810

1.

Rec ord the configuration data:

a. Connec t the electronic service tool to the

diagnostic connector. Refer to Troubleshooting,

“Electronic Service Tools”.

b. Print the parameters from the “Configuration”

screen on the electronic service tool. If a printer

is unavailable, record all of the parameters.

Record any logged diagnos tic codes and

Replacing

the

ECM

logged event codes for your records. Record

the injector codes from the “Calibrations”

screen in the “Service” menu on the electronic

service tool.

NOTICE

Keep all parts clean from contaminants.

c.

Use the “Copy

Configuration/ECM

Contaminants may cause rapid wear and shortened

component life.

The Electronic Control Module (ECM) contains no

moving parts. Replacement of the ECM can be

costly. Replacement can also be a time consuming

task. Follow the troubleshooting procedures in this

manual in order to ensure that replacing the ECM will

correct the fault. Verify that the suspect ECM is the

cause of the fault.

Note: Ensure that the ECM is receiving power and

that the ECM is properly wired to the negative battery

circuit before a replacement of the ECM is attempted.

Refer to Troubleshooting, “Electrical Power Supply

Circuit - Test”.

A test ECM can be used to determine if the ECM is

faulty. Install a test ECM in place of the suspect ECM.

Flash program the correct flash file into the test ECM.

Program the parameters for normal operation of the

engine. The parameters must match the parameters

in the suspect ECM. Refer to the following test steps

for details. If the test ECM resolves the fault, connect

the suspect ECM. Verify that the fault returns. If the

fault returns, replace the suspect ECM.

Note: When a new ECM is not available, you may

need to remove an ECM from an engine that is not

in service. The interlock code for the replacement

ECM mus t match the interlock code for the suspect

ECM. Be sure to record the parameters from the

replacement ECM on the “Parameters Worksheet”.

Use the “Copy Configuration/ECM Replacement”

feature that is found under the “Service” menu on

the electronic service tool.

NOTICE

If the flash file and engine application are not matched,

engine damage may result.

Perform the following procedure in order to replace

the ECM:

Replacement” feature that is found under the

“Service” menu on the electronic serv ice tool.

Select “Load from ECM” in order to copy the

configuration data from the suspect ECM.

Note: If the “Copy Configuration” process fails and

the parameters were not obtained in Step 1.b, the

parameters must be obtained elsewhere. Some of the

parameters are stamped on the engine information

plate. Most of the parameters must be obtained from

the factory.

2. Remove the ECM:

a. Turn the keyswitch to the OFF position.

b. Disconnect the P1 and P2 connectors from

the ECM.

c. Disconnect the ECM ground s trap.

d. Remove the mounting bolts from the ECM.

3. Install the replacement ECM:

a. Use the old mounting hardware to install the

replacement ECM.

b. Connec t the ECM ground strap.

c. Connec t the P1 and P2 connectors. Tighten

the ECM connector (allen head screw) to

the proper torque. Refer to Troubleshooting,

“Electrical Connectors - Inspect” for the correct

torque value.

4. Configure the replacement ECM:

a. Flash program the flash file into the ECM.

Refer to Troubleshooting, “Flash Programming”

for the correct procedure.

![]() KE, NR6224

KE, NR6224

13

Troubleshooting Section

b. Use the electronic service tool to match the

engine application and the interlock code if

the replacement ECM was used for a different

application.

c. If the “Copy Configuration” process from

Step 1.b was successful, return to the “Copy

Configuration/ECM Replacement” screen on

the electronic service tool and select “Program

ECM”. Proceed to Step 4.e when programming

is c omplete.

d. If the “Copy Configuration” process from Step

1.b was unsuccessful, manually program the

ECM parameters. The parameters must match

the parameters from Step 1.b.

e. Program the engine monitoring system, if

necessary.

f. Load the injector trim files for the injectors.

Refer to Troubleshooting, “Injector Trim File”.

g. Calibrate the engine speed/timing. Refer

to Troubleshooting, “Engine Speed/Timing

Sensor - Calibrate”.

Every generated code is stored in the permanent

memory of the ECM. The codes are logged.

Logged codes may not indicate that a repair is

needed. The fault may have been temporary. The

fault may have been resolved since the logging of

the code. If the system is powered, it is possible

to generate an active diagnostic code whenever a

component is disconnected. When the component is

reconnected, the code is no longer active. Logged

codes may be useful to help troubleshoot intermittent

faults. Logged codes can also be used to review

the performance of the engine and of the electronic

system.

Event Code

An event code is generated by the detection of an

abnormal engine operating condition. For example,

an event code will be generated if the oil pressure is

too low. In this case, the event c ode indicates the

symptom of a fault.

Self-Diagnostics

i02548823

The Electronic Control Module (ECM) has the ability

to detect faults with the electronic sys tem and with

engine operation. When a fault is detected, a code is

generated. An alarm may also be generated. There

are two types of codes:

• Diagnostic

• Event

Diagnostic Code – When a fault with the electronic

system is detected, the ECM generates a diagnostic

code. This indicates the specific fault with the

circuitry.

Diagnostic codes can have two different states:

• Active

• Logged

Active Code

An active diagnostic code indicates that an active

fault has been detected. Activ e c odes require

immediate attention. Always service active codes

prior to servicing logged codes.

Logged Code

![]() 14

14

Troubleshooting Section

KENR6224

Sensors

and

Electrical

i02548835

Connectors

Table 3

|

Connector |

Function |

|

J1/P1 |

ECM Connector (70-Pin Engine Harness) |

|

J2/P2 |

ECM Connector (“120-Pi n Engine Harness”) |

|

J61/P61 |

Customer Connector (Optional) (40-Pin Connector) |

|

J63/P63 |

Diagnostic Connector (9-Pin Connector) |

|

J100/P100 |

Coolant Temperature Sensor (2-Pin Connector) |

|

J103/P103 |

Inlet Manifold Temperature Sensor (2-Pin Connector) |

|

J105/P105 |

Fuel Temperature Sensor (2-Pin Connector) |

|

J200/P200 |

Inlet Manifold Pressure Sensor (3-Pin Connector) |

|

J201/P201 |

Engine Oil Pressure Sensor (3-Pin Connector) |

|

J203/P203 |

Atmospheric Pressure Sensor (3-Pin Connector) |

|

J300/P300 |

Injector Solenoid Harness (12-Pin Connector) |

|

J400/P400 |

Engine Timing Cal ibr ation Probe (2-Pin Connector) |

|

J401/P401 |

Crankshaft Position Sensor (2-Pin Connector) |

|

J402/P402 |

Camshaft Position Sensor (2-Pin Connector) |

![]()

![]()

![]() KENR6224

KENR6224

15

Troubleshooting Section

Illustration 4

Block diagram for the 2506-15 engine components

(1) 12 Pin Connector (9) Timing Calibration Probe

(2) Electronic Control Module (ECM) (10) Timing Calibration Probe Connector

(3) Electronic Unit Injectors (11) Atmospheric Pressure Sensor

(4) Crankshaft Position Sensor (12) Inlet Manifold Temperature Sensor

(5) 36 - 1 Tooth Gear (13) Inlet Manifold Pressure Sensor

(6) 120 Pin Connector (14) Coolant Temperature Sensor

(7) 36 + 1 Tooth Gear (15) Engine Oil Press ure Sensor

(8) Camshaft Position Sensor (16) Fuel Temperature Sensor

g01278058

![]()

![]()

![]() 16

16

Troubleshooting Section

KENR6224

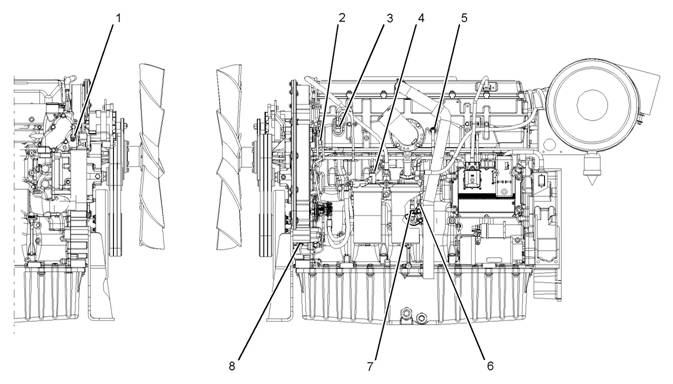

Illustration 5

Locations of the sensors on the 2506-15 engine

(1) Coolant temperature sensor

(2) Camshaft position sensor

(3) Inlet manifold pressure sensor

(4) Fuel temperature sensor

(5) Inlet manifold temperature sensor

(6) Engine oil pres sure sensor

(7) Atmospheric pressure sensor

(8) Crank shaft position sensor

g01279372

![]()

![]()

![]() KENR6224

KENR6224

17

Troubleshooting Section

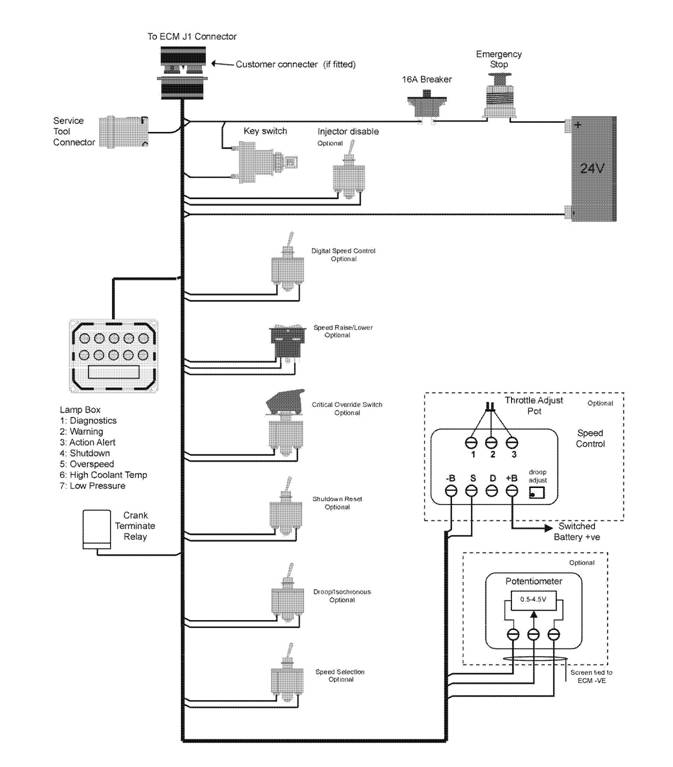

Illustration 6

Block diagram for the machine components

g01278305

| |||||||||||||||||||||||||||||||||

Troubleshooting Section

KENR6224

Engine Wiring

Information

i02548945

1.

2.

Stop the engine. Turn the keyswitch to the OFF

position.

Disconnect the negative battery cable from the

battery. If a battery disconnect switc h is installed,

open the switch.

The wiring schematics are revised periodically.

The wiring schematics will change as updates are

made to the machine harness. For the most current

information, always check the revision number of the

schematic. Use the schematic with the latest revision

number.

Harness Wire Identification

Perkins identifies all wires with eleven solid c olors.

The circuit number is stamped on the wire at a 25 mm

(1 inch) spacing. Table 4 lists the wire colors and the

color codes.

Table 4

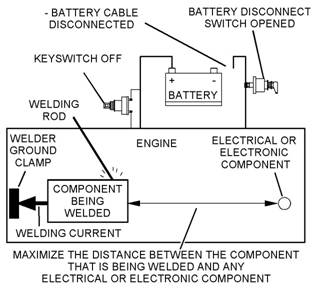

Illustration 7

Service welding guide (typical diagram)

g01143634

Welding on a Machine that is Equipped

with an Electronic Control System ( ECM)

Proper welding procedures are necessary in order

to avoid damage to the engine’s electronic c ontrol

module, sensors, and associated components. The

component that requires welding should be removed.

When welding on a machine that is equipped with an

ECM and removal of the component is not possible,

the following procedure must be followed. This

procedure provides the minimum amount of risk to

the electronic components.

NOTICE

Do not ground the welder to electrical components

such as the ECM or sensors. Improper grounding can

cause damage to the drive train bearings, hydraulic

components, electrical components, and other com-

ponents.

Clamp the ground cable from the welder to the com-

ponent that will be welded. Plac e the clamp as close

as possible to the weld. This will help reduce the pos-

sibility of damage.

3.

4.

5.

Connect the welding ground cable as close

as possible to the area that will be welded.

Components which may be damaged by welding

inc lude bearings, hydraulic components, and

electrical/electronic components.

Protect the wiring harness from welding debris

and from spatter.

Weld the materials by using standard welding

methods.

![]()

![]()

![]() KENR6224

KENR6224

19

Troubleshooting Section

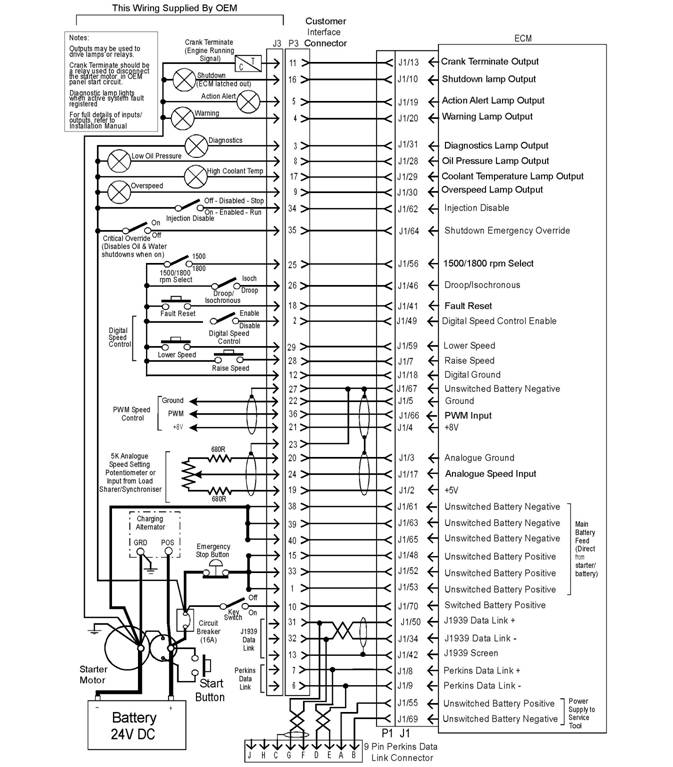

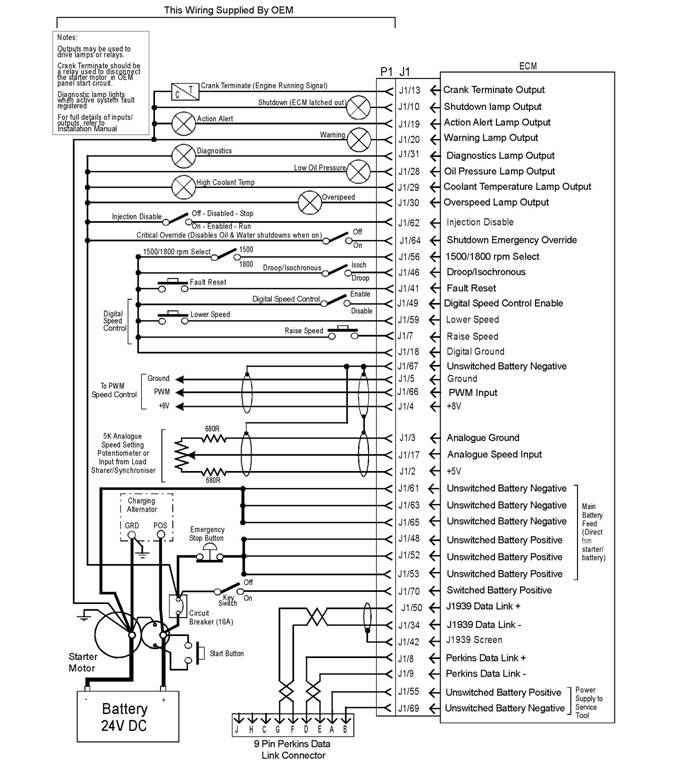

Illustration 8

Schematic diagram for a machine with an OEM connector

g01275859

![]()

![]()

![]() 20

20

Troubleshooting Section

KENR6224

Illustration 9

Schematic diagram for a machine without an OEM connector

g01275860

![]()

![]() KENR6224

KENR6224

21

Troubleshooting Section

Programming

Par ame ters

i02549443

Since factory passwords contain alphabetic

characters, the Perkins Electronic Service Tool

(EST) must be used to perform these functions. In

order to obtain factory passwords, proceed as if you

already have the pass word. If factory passwords are

Programming Parameters

The Perkins Electronic Service Tool (EST) can be

used to view certain parameters that can affect

the operation of the engine. The Perkins EST can

also be used to change certain parameters. The

parameters are stored in the Electronic Control

Module (ECM). Some of the parameters are

protected from unauthoriz ed changes by passwords.

Parameters that can be changed have a tattletale

number. The tattletale number shows if a parameter

has been changed.

i02549444

Factory Passwords

needed, the Perkins EST will request the factory

pas swords and the Perkins EST will display the

information that is required to obtain the passwords.

For the worksheet that is used for acquiring factory

passwords, refer to programming parameters

Troubleshooting, “Factory Passwords Worksheet”.

i02549455

Factory Passwords Worksheet

Note: A mistake in recording these parameters will

result in incorrect passwords.

NOTICE

Operating the engine with a flash file not des igned for

that engine will damage the engine. Be sure the flash

file is correct for your engine.

Note: Factory passwords are provided only to

Perkins dealers and distributors.

Factory passwords are required to perform each of

the following functions:

• Program a new Electronic Control Module (ECM).

When an ECM is replaced, the system

configuration parameters must be programmed

into the new ECM. A new ECM will allow these

parameters to be programmed once without factory

pas swords. After the initial programming, some

parameters are protected by factory passwords.

• Clear event codes.

Most event codes require the use of factory

pas swords to clear the code once the code has

been logged. Clear these codes only when you are

certain that the fault has been corrected.

• Unlock parameters.

Factory passwords are required in order to unlock

certain system configuration parameters. Refer

to Troubleshooting, “System Configuration

Parameters”.

![]() 22

22

Troubleshooting Section

KENR6224

Table 5

Factory Passwords Worksheet

Note: If you do not have the part number for the flash

file, us e “PTMI” on the Perkins Internet.

Dealer Code

Customer ’s Name

Address

Telephone Number

Information From the Engine Information Plate

Engine Serial Number

Full Load Setting

Full Torque Setting

Information From the Diagnostic Clock

Engine Hours

Information From the “Factory Password Entry

Screen” on the Electronic Service Tool

Electronic Service Tool

Serial Number

Engine Serial Number

ECM Serial Number

Total Tattletale

Reason Code

From Interlock(1)

To Interlock(1)

Fact ory Passwords

Factory Password (No. 1)

Factory Password (No. 2)

(1) This parameter is required when the engine is being rerated.

This parameter is displayed only when the engine is being

rerated.

i02549457

Flash Programming

Flash Programming – A method of loading a flash

file into the Electronic Control Module (ECM)

The electronic service tool can be utilized to

flash program a flash file into the ECM. The flash

programming transfers the flash file from the PC to

the ECM.

Flash Programming a Flash File

1. Obtain the part number for the new flash file.

Note: You must have the engine serial number in

order to search for the part number for the flash file.

2. Connect the electronic service tool to the service

tool connector.

3. Turn the keyswitch to the ON position. Do not start

the engine.

4. Select “WinFlash” from the “Utilities” menu on the

electronic service tool.

Note: If “WinFlash” will not communicate with the

ECM, refer to Troubleshooting, “Electronic Service

Tool Will Not Communicate with ECM”.

5. Flash program the flash file into the ECM.

a. Select the engine ECM under the “Detected

ECMs”.

b. Press the “Browse” button in order to select

the part number of the flash file that will be

programmed into the ECM.

c. When the correct flash file is selected, press

the “Open” button.

d. Verify that the “File Values” match the

application. If the “File Values” do not match

the application, search for the correct flash file.

e. When the correct flash file is selected, press

the “Begin Flash” button.

f. The electronic service tool will indicate when

flash programming has been successfully

completed.

6. Start the engine and check for proper operation.

a. If a diagnostic code 0268-02 is generated,

program any parameters that were not in the

old flash file.

b. Access the “Configuration” screen under

the “Service” menu in order to determine

the parameters that require programming.

Look under the “Tattletale” column. All of the

parameters should have a tattletale of 1 or

more. If a parameter has a tattletale of 0,

program that parameter.

![]() KENR6224

KENR6224

23

Troubleshooting Section

“WinFlash” Error Messages

If you receive any error messages during flash

programming, click on the “Cancel” button in order

to stop the process. Access the information about

the “ECM Summary” under the “Information” menu.

Ensure that you are programming the correct flash

file for your engine.

i02549465

Injector Trim File

The electronic service tool is used to load the injector

trim files into the Electronic Control Module (ECM).

The injector trim files must be loaded into the ECM if

5.

6.

7.

8.

9.

Connect the electronic service tool to the

service tool connector. Refer to Troubleshooting,

“Electronic Service Tools”.

Turn the keyswitch to the ON position.

Select the following menu options on the electronic

service tool:

• Service

• Calibrations

• Injector Trim Calibration

Select the appropriate cylinder.

Click on the “Change” button.

|

|

• An injector is replaced.

• The ECM is replaced.

• Diagnostic code 0253-02 is active.

• Injectors are exchanged between cylinders.

Exchanging Electronic Unit Injectors

Exchanging injectors can help determine if a fault is

in the injector or in the cylinder. If two injectors that

are currently installed in the engine are exchanged

between cylinders, the injector trim files can also

be exchanged. Press the “Exchange” button at the

bottom of the “Injector Trim Calibration” screen on

the electronic service tool. Select the two injectors

that will be exchanged and press the “OK” button.

The tattletale for the injectors that were exchanged

will increase by one.

Note: The serial number for the injector and the

confirmation code number for the injector are located

on the injector.

1. Record the serial number and the confirmation

code numberfor each injector.

2. Obtain the injector trim file by one of the following

methods:

Internet.

replacement injector.

3. Enter the serial number for the injector in the

search field.

4. Download the injec tor trim file to the PC. Repeat

this procedure for each injector, as required.

10. Select the appropriate injector trim file from the

PC.

11. Click on the “Open” button.

12. If you are prompted by the electronic service

tool, enter the confirmation code number for the

injector into the field.

13. Click on the “OK” button.

The injector trim file is loaded into the ECM.

14. Repeat the procedure for each cylinder, as

required.

![]() 24

24

Troubleshooting Section

KENR6224

System

Conf iguration

ECM Serial Number

This is a read only parameter that displays the serial

Parameters

System Configuration

Parameters

i02549472

number of the ECM.

ECM Software Release Date

This parameter is defined by the ECM software

and this parameter is not programmable. The ECM

software release date is used to provide the version

of the software. The customer parameters and the

software change levels can be monitored by this

System configuration parameters affect the emissions

of the engine or the power of the engine. System

configuration parameters are programmed at the

factory. Normally, system configuration parameters

would never need to be changed through the life of

the engine. System configuration parameters must

be reprogrammed if an Electronic Control Module

(ECM) is replaced. System configuration parameters

do not need to be reprogrammed if the ECM software

is changed. The correct values for these parameters

are stamped on the engine information ratings plate.

Factory passwords are required to change these

parameters. The following information is a description

of the system configuration parameters.

Full Load Setting (FLS)

The full load setting is a number that represents

the adjustment to the fuel system that was made

at the factory in order to fine tune the fuel sy stem.

The correct value for this parameter is stamped on

the engine information ratings plate. If the ECM is

replaced, the full load setting mus t be reprogrammed

in order to prevent a 0268-02 diagnostic code from

becoming active.

Full Torque Setting (FTS)

Full torque setting is similar to full load setting. If

the ECM is replaced, the full torque setting must

be reprogrammed in order to prevent a 0268-02

diagnostic code from becoming active.

Software Part number

This is the part number of the software that is flashed

into the ECM.

Engine Serial Number

When a new ECM is deliv ered, the engine serial

number in the ECM is not programmed. The engine

serial number should be programmed to matc h the

engine serial number that is stamped on the engine

information plate.

date. The date is provided in the month and the year

(AUG06). AUG is the month (August). 06 is the year

(2006).

Critical Override Switch

If equipped, the critical override switch allows the

engine to continue running even if engine oil pressure

or coolant temperature have reached the shutdown

limit for the engine. If the engine is run in this

condition, the engine warranty is canc elled and any

events that occur are s tored in the ECM with the time

and the date. Implementation of this facility requires

a fac tory password.

Total Tattletale

This parameter displays the total number of changes

that have been made to the configuration parameters.

![]() KENR6224

KENR6224

25

Troubleshooting Section

Configuration Parameters

Table 6

|

Screen Order |

Configuration Parameter Description |

Read/Write Security |

|

1 |

Selected Engine Rating |

|

|

2 |

Rating Number |

RW2(1) |

|

3 |

Rated Frequency |

R(2) |

|

4 |

Rated Genset Speed |

R(2) |

|

5 |

Rated Real Genset Power |

R(2) |

|

6 |

Rated Apparent Genset Power |

R(2) |

|

7 |

Engine Rating Application Type |

R(2) |

|

8 |

External Speed Selection Switch Installed |

RW2(1) |

|

9 |

ECM Identification Parameters |

|

|

10 |

Equipment ID |

RW2(1) |

|

11 |

Engine Serial Number |

RW3(3) |

|

12 |

ECM Serial Number |

R(2) |

|

13 |

ECM Software Part Number |

R(2) |

|

14 |

ECM Software Release Date |

R(2) |

|

15 |

ECM Software Description |

R(2) |

|

16 |

Security Access Parameters |

|

|

17 |

Total Tattl etale |

R(2) |

|

18 |

Engine/Gear Parameters |

|

|

19 |

Engine Acceleration Rate |

RW2(1) |

|

20 |

Droop/Isochronous Switch Installed. |

RW2(1) |

|

21 |

Droop/Isochronous Selection |

RW2(1) |

|

22 |

Engine Speed Droop |

RW2(1) |

|

23 |

Critical Override Switch Installed |

RW2(1) |

|

24 |

Digital Speed Control Installed |

RW2(1) |

|

25 |

Speed Control Minimum Speed |

RW2(1) |

|

26 |

Speed Control Maximum Speed |

RW2(1) |

|

27 |

Digital Speed Control Ramp Rate |

RW2(1) |

|

28 |

Crank Terminate Speed |

RW2(1) |

|

29 |

I/O Configuration Parameters |

|

|

30 |

Desired Speed Input Arrangement |

RW2(1) |

|

31 |

Fuel Enable Input Configurati on |

RW2(1) |

|

32 |

System Parameters |

|

|

33 |

Full Load Setting (FLS) |

RW3(3) |

|

34 |

Full Torque Setting (FTS) |

RW3(3) |

|

35 |

Governor Gain Factor |

RW1(4) |

|

36 |

Governor Minimum Stability Factor |

RW1(4) |

|

37 |

Governor Maximum Stability Factor |

RW1(4) |

(continued)

![]() 26

26

Troubleshooting Section

KENR6224

(Table 6, contd)

|

38 |

Passwords |

|

|

39 |

Customer Password 1 |

RW2(1) |

|

40 |

Customer Password 2 |

RW2(1) |

(1)

(2)

(3)

(4)

Read/write with a customer password

Read only

Read/write with a factory password

Read/write without a password

Customer Specified Parameters

Customer specified parameters allow the engine to

be configured to the exact needs of the application.

Customer parameters may be changed repeatedly as

a customer’s operation changes.

The following information is a brief desc ription of the

customer specified parameters.

Rating Duty Selection

This parameter enables selection of the engine rating

from a series of maps within the ECM. Changing the

rating requires a cus tomer password. The available

ratings within the ECM will vary with the type of

engine and the specification of the engine.

Rated Frequency

This parameter displays the rated frequency of the

genset. This is determined by the rating selection

and the status of the external speed selection s witch.

This parameter is read only.

Rated Speed

This parameter displays the rated speed of the

engine. This is determined by the rating selection

and the status of the external speed selection s witch.

This parameter is read only.

Rated Real Genset Power

This parameter displays the maximum power in kW

of the currently s elected rating. This parameter is

read only.

Rated Apparent Genset Power

This parameter displays the maximum power in kVA

of the currently s elected rating. This parameter is

read only.

Rating Configuration

This parameter displays the configuration of the

currently selected rating. The following list gives the

possible configurations:

• Standby power

• Limited time prime power

• Prime power

• Continuous or baseload power

For definitions of these ratings, refer to ISO8528.

This parameter is read only.

Note: Not all of the above rating configurations will

be available in the software files of every ECM.

E xternal Speed Selection Switch Enable

For dual s peed applications with an external

speed selection switch, this parameter enables the

functionality of the speed selection switch within

the s oftware. Changing this parameter requires a

customer password.

Engine Startup Acceleration Rate

This parameter enables the ac celeration rate of

the engine in RPM per second to be programmed.

The parameter can be programmed from idle speed

to rated speed. Control of this parameter enables

any overshoot in speed on start-up to be limited.

Changing this parameter requires a c ustomer

pas sword.

Droop/Isochronous Switch Enable

This parameter determines whether the external

droop/isochronous switch is enabled or disabled.

Changing this parameter requires a c ustomer

pas sword.

![]() KENR6224

KENR6224

27

Troubleshooting Section

Droop/Isochronous Selection

The engine will normally be run in isochronous mode.

This means that the engine speed will not change,

regardless of the load. If the engine needs to operate

in parallel with another genset or the engine needs

to operate in parallel with the grid, it is nec essary to

operate the engine in droop mode in order to ensure

the stability of the system. This parameter enables

droop/isochronous running selection. Changing this

parameter requires a customer pass word.

Note: If an external droop/isochronous switch is

enabled, the position of this switch will override the

“Droop/Is ochronous” selection.

Engine Speed Droop

If droop operation is selected, this parameter

allows the setting of percentage droop. This is the

percentage of speed reduction with an increase in

load. This parameter has no effect when the engine

is running in isochronous mode. Changing this

parameter requires a customer pass word.

Digital Speed Cont rol Installed

This parameter determines whether input from the

raise/lower switch controls the speed of the engine.

If digital speed control is not installed, the speed of

the engine is controlled by inputs from the analog

throttle or the PWM throttle. This depends on the

input that is selected in the desired speed input

configuration. Changing this parameter requires a

customer password.

Digital S peed Control Minimum Speed

This setting determines the minimum speed range of

both the raise/lower control and the analog control.

For example, if this is set to 100 RPM and the

nominal engine speed is s elected to 1500 RPM, the

minimum speed setting is 1400 RPM. This parameter

does not affect the range of the PWM speed control

as this control has a fixed minimum limit and a fixed

maximum limit. Changing this parameter requires a

customer password.

Digital S peed Control Maximum Speed

This setting determines the maximum speed range of

both the raise/lower control and the analog control. If

this is set to 100 RPM and the nominal engine speed

is selected to 1500 RPM, the maximum speed setting

is 1600 RPM. This setting does not affect the range

of the PWM speed control as this c ontrol has a fixed

minimum limit and a fixed maximum limit. Changing

this parameter requires a customer password.

Digital Speed Control Ramp Rate

This setting determines the rate of change of engine

speed in RPM when the raise/lower switch inputs are

closed. Changing this parameter requires a customer

pas sword.

Crank Terminate Speed

This parameter is used to set the engine speed that

is required before the output from the crank terminate

relay is switched. Changing this parameter requires a

customer password.

Desired Speed Input Arrangement

If a digital speed control is not installed, this

parameter enables selection of either an analog

throttle, a PWM throttle or an ex ternal CAN Bus

speed control. The inputs from the analog throttle,

the PWM throttle or the CAN Bus speed control

are normally used with genset load sharing and

synchronizing controllers. Changing this parameter

requires a customer password.

Note: If a PWM throttle, an analog throttle or a CAN

Bus speed control is selected but there are no inputs

to the terminals for the selected speed control, the

engine will default to running at 1100 RPM.

If a PWM throttle, an analog throttle or a CAN Bus

speed control is not used, the digital s peed control

should be selected.

Fuel Enable Input Configuration

This parameter enables the selection of switch to

battery positive or CAN input for the control of the

injector On and injector Off.

Governor Gain Parameters

The following items are the adjustable parameters for

gov ernor gain:

• Governor Gain Factor

• Governor Minimum Stability Factor

• Governor Maximum Stability

Note: No engineering units are associated with these

numbers.

Note: The programmable range is wide for flexibility.

Values of 1 to 40000 are valid. The full range of this

parameter may not be used on any system. Do not

expect to use the whole range.

![]()

![]() 28

28

Troubleshooting Section

KENR6224

|

|

Governor Gain Factor

The governor gain factor is multiplied to the difference

between desired speed and actual speed.

large, the engine speed can overshoot the desired

speed. The overshoot is caused by an excessive

correction or an instability of a steady state.

that is nec essary to accelerate the engine to the

des ired speed must be obtained by increas ing the

stability terms to a higher value. As this process is

slow, the response of the engine speed is slow.

Governor Minimum/Maximum Stability

Factor

The stability factor terms work in order to eliminate a

steady state speed error. There are two gain terms

that are used for stability. If the error is greater than

20 RPM and if the error is increasing, the maximum

stability gain is functioning. If the error is less than

20 RPM, the minimum stability gain is used. This

function allows the use of a high gain that would

2.

3.

4.

5.

6.

Start the engine. On the engine mounted genset

control panel, check that the engine has reached

rated speed. This panel will serve as the reference

point for the speed during this procedure.

Enter the “Configuration Parameters” screen on

the electronic service tool.

Determine the desired scenario in order to tune

the engine. For example, check if the engine has

poor response during specific load assignments

or specific load dumps.

Perform the desired load change that is detailed

in step 4. Check the response of the engine by

viewing the following parameters.

• The engine speed on the control panel on the

genset

• The frequency response of the system bus to

the load change

• Listening to the response of the engine

Use the listed suggestions in order to determine

the gains that require adjustment.

|

|

engine is operating near the desired speed.

stability gain is set too high, the governor will

provide more fuel than the amount that is

nec essary to bring the error to zero. The additional

fuel will cause the engine speed to overshoot and

the engine to produce excessive combustion noise.

stability gain is set too low, excessive time is taken

in order to stabilize the engine s peed.

Tuning Procedure

1. Turn the keyswitch to the OFF/RESET position.

Before the tuning procedure is started, connect

the electronic serv ice tool and then check

that engine overspeed protection is enabled.

Engine overspeed is configured on the

“Service\Monitoring System” sc reen on the

electronic service tool.,

NOTICE

Performing engine governor tuning without engine

overspeed protection could result in serious engine

damage. Ens ure that this parameter is ON while

performing this proc edure.

Note: Usually, the gain factor of the governor should

be lower than the minimum stability fac tor of the

gov ernor in order to obtain optimum performance.

The maximum stability factor is typically a smaller

value than the minimum stability gain and the

gov ernor gain factor.

7. Repeat steps 5, 6 and 7 until a desired engine

response can be met. Use large adjustments

(10% of original gain) initially to generally tune the

engine in the proper manner. As the response

gets closer to the desired value, increase the

gains in smaller increments (1% of total gain).

Customer Password 1, Customer

Password 2

Customer passwords are the programmable

parameters that can be used to protect certain

configuration parameters from any unauthorized

changes.

Engine monitoring

Perkins provides an engine monitoring system that

is ins talled at the factory. The system monitors the

following parameters:

• Engine oil pressure

• Coolant temperature

![]() KENR6224

KENR6224

29

Troubleshooting Section

•

•

•

•

Intake manifold air temperature

Engine speed

Boost pressure

Fuel temperature

Diagnostic codes that are stored in memory are

called Logged diagnostic codes. The fault may have

been temporary or the fault may hav e been repaired

since the fault was logged. For this reason, logged

codes do not necessarily mean that something needs

to be repaired. Logged diagnostic codes are meant

to be an indication of probable causes for intermittent

faults.

The monitoring system has three levels of operation.

The levels are described below.

Warning Operation

In the Warning condition, the ECM causes the

warning lamp to come ON. The warning lamp

indicates that a fault has been detected by the engine

monitoring system. No further action by the ECM or

the engine occurs.

Action Alert Operation

In the Action Alert condition, the ECM causes the

action alert lamp to come on. The Action Alert lamp

indicates that a fault has been detected by the engine

monitoring system. This condition is normally wired

in order to cause a shutdown and the shutdown is

controlled by the control panel on the mac hine.

Shutdown Operation

If the fault reaches the Shutdown c ondition, the ECM

causes the shutdown lamp to come on. Unless the

engine is in a Critical Override condition, the engine

will shut down.

Monitoring the Fuel Temperature

The fuel temperature sensor monitors the fuel

temperature. The signal from the sensor allows

the ECM to compensate for changes in the fuel

temperature by adjusting the fuel rate for constant

power.

The sensor is also used to warn the operator of

exces sive fuel temperature with a diagnostic event

code. Excessive fuel temperatures can adversely

affect engine performance.

Self-Diagnostics

The electronic system has the ability to diagnose

faults. When a fault is detected, a diagnostic code

is generated and the diagnostic code is stored

in permanent memory (logged) in the ECM. The

diagnostic lamp is also activated.

When diagnostic codes occur, the diagnostic codes

are referred to as Active diagnostic codes. Active

diagnostic c odes indicate that a fault of some kind

currently exists.